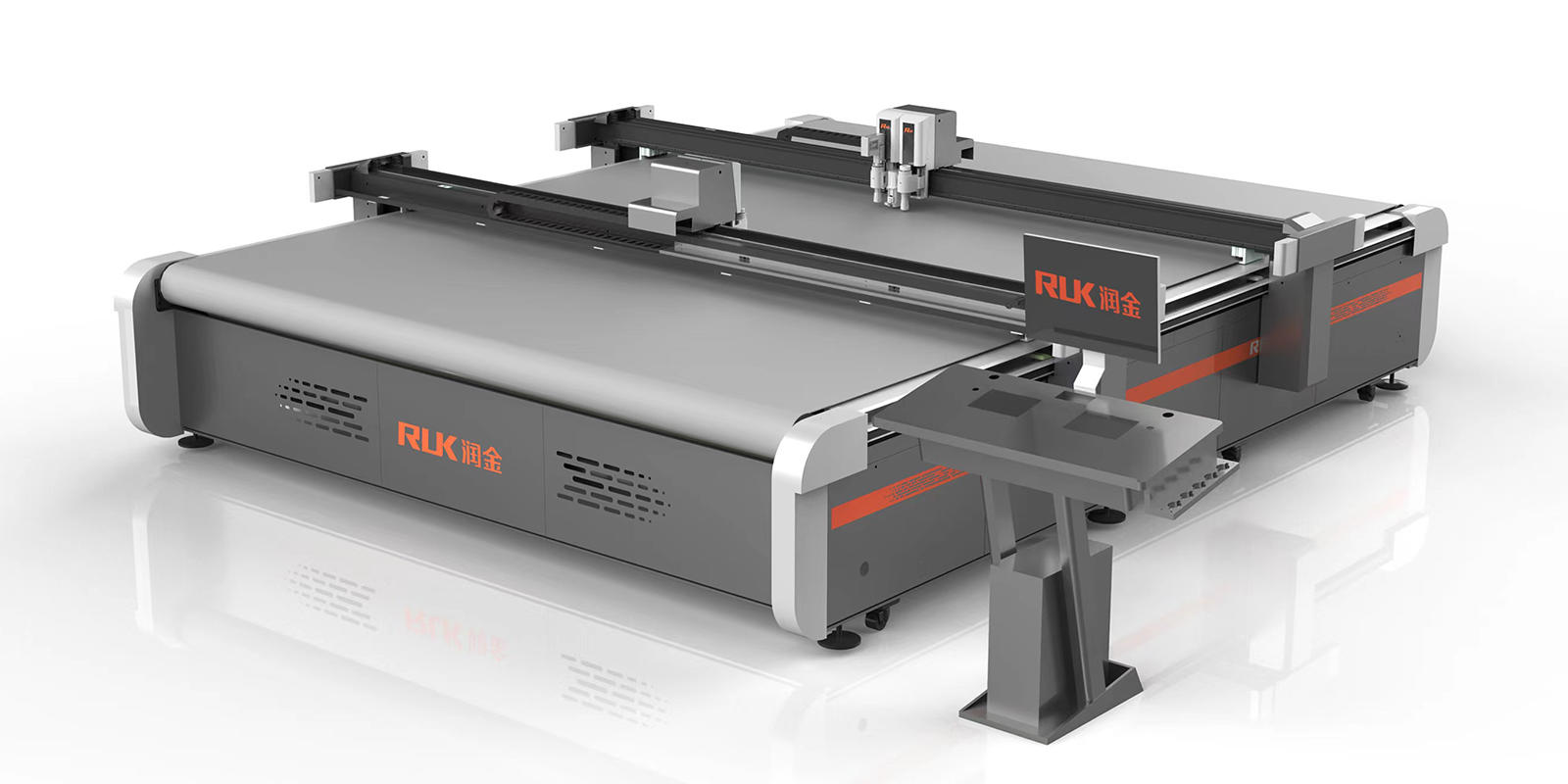

Professional Flexible Materials Automated Cutting Solutions.

Basic functions of magnetic stickers

In flatbed cutting machines, the main function of magnetic stickers is to help fix and position materials. Since flatbed cutting machines need to cut various materials of plates, films, fabrics, etc., accurate positioning and stable fixation are essential. Magnetic stickers can be firmly adsorbed on the metal platform of the cutting machine to fix the material to be cut in a specified position to prevent the material from moving or deviating during the cutting process, which is very important to ensure the accuracy and quality of cutting.

Specific applications of magnetic stickers in flatbed cutting machines

1. Material positioning and fixation

Flatbed cutting machines often handle materials of different sizes and materials. In order to ensure that the material does not move during the cutting process, magnetic stickers are widely used for material positioning and fixation. Operators can place magnetic stickers on the edge or corner of the material according to the size and shape of the material so that it fits firmly on the cutting platform. This can effectively prevent the material from sliding or warping and ensure the accuracy of the cutting path.

2. Template fixation and guidance

In some cutting tasks that require the use of templates, magnetic stickers can play a guiding role. Operators can fix magnetic stickers around the template to ensure that the template does not move during the cutting process. This not only improves the accuracy of cutting, but also reduces the friction between the template and the material, extending the service life of the template.

3. Assisted automated operation

As the automation level of flatbed cutting machines increases, magnetic stickers are gradually used in automated operations. For example, some flatbed cutting machines are equipped with magnetic sensors that automatically adjust the cutting path or tool by identifying the position of the magnetic sticker. This application reduces human intervention and improves production efficiency and cutting accuracy.

4. Convenient process switching

During the production process, it is often necessary to quickly change different materials or cutting templates. The reusable nature of magnetic stickers makes it very suitable for this scenario. The operator only needs to easily remove the magnetic sticker to change the material or template without the use of tools or glue, which greatly simplifies the process of process switching and saves time and manpower.

5. Reduce material waste

Magnetic stickers can effectively reduce material waste. Due to its precise positioning function, the cutting machine is able to optimize cutting within the maximum area of the material, avoiding waste caused by material sliding or inaccurate positioning. In addition, the reusable nature of magnetic stickers also reduces production costs and further improves resource utilization.

Ningbo Ruking Intelligent Technology Co., Ltd. Room 402, 4th Floor, Building 12, Xinchanyungu Industrial Park, Jiangkou Street, Fenghua District, Ningbo City, Zhejiang Province

Tel: +86-18167226377

Email: [email protected]

Copyright © 2023 by Ningbo Ruking Intelligent Technology Co., Ltd. Rights Reserved.

China Digital Cutter manufacturers Custom Digital Cutter Suppliers