Professional Flexible Materials Automated Cutting Solutions.

In the evolving landscape of modern manufacturing, efficiency and precision are paramount. The flatbed cutting machine emerges as a pivotal tool, adept at handling an array of materials, including plastics, foam, leather, and reflective materials. Its integration into the manufacturing process not only enhances cutting efficiency but also ensures quality, making it indispensable for industries striving for excellence.

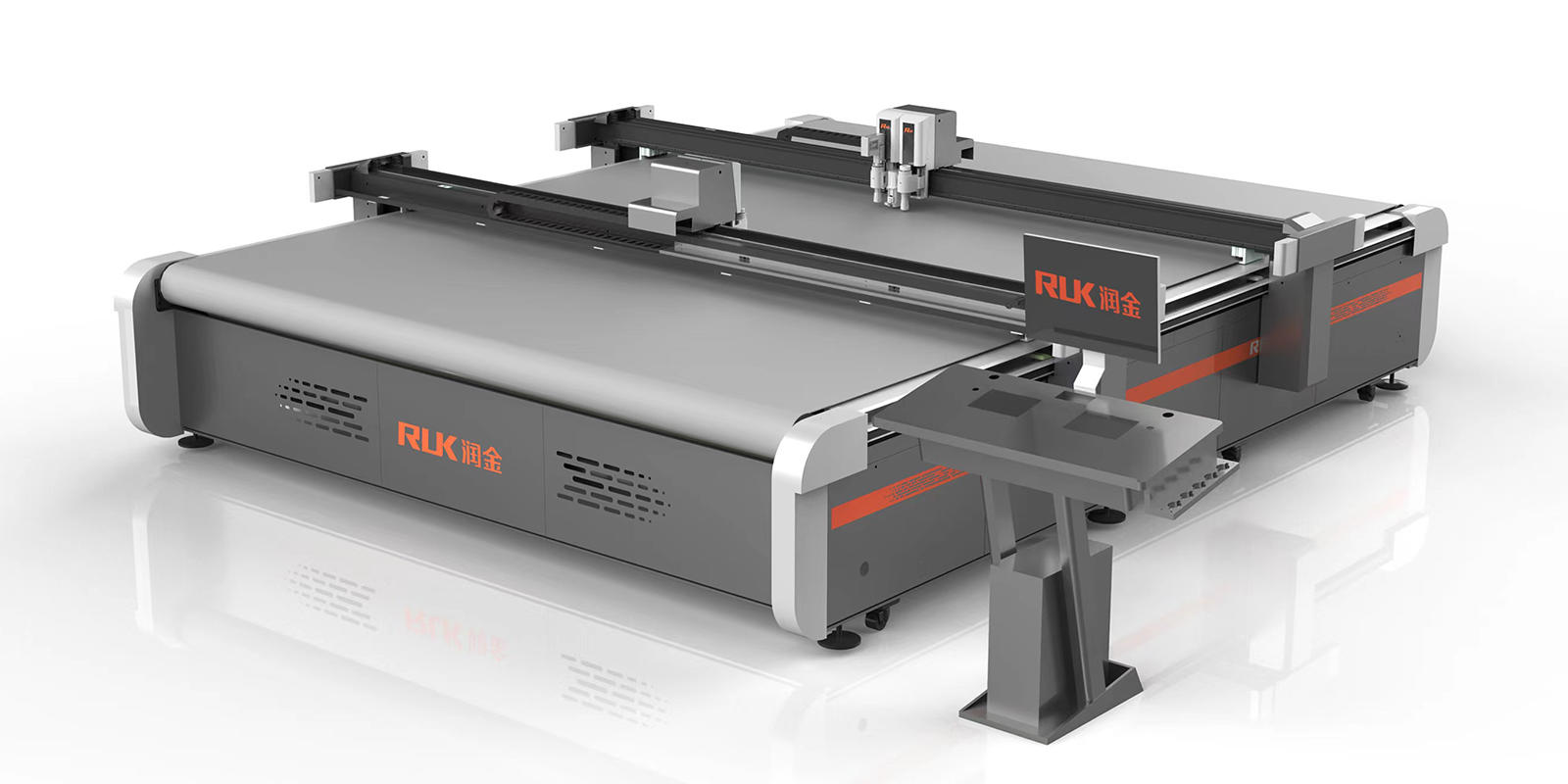

Understanding the Flatbed Cutting Machine

The flatbed cutting machine is renowned for its versatility and precision. Designed to cater to diverse materials, it leverages advanced technology to deliver unparalleled accuracy. This machine employs a flat surface where the material is laid out for cutting, allowing for intricate designs and patterns that are otherwise challenging with conventional cutting methods.

Cutting Efficiency at Its Best

Efficiency in manufacturing translates to reduced waste and optimized resource utilization. The flatbed cutting machine excels in this domain by minimizing material wastage and ensuring precise cuts, thereby yield. Its automated features significantly reduce manual intervention, streamlining the production process and enhancing output rates.

Applications Across Various Materials

The adaptability of the flatbed cutting machine is evident in its wide-ranging applications. For plastics, it ensures clean cuts without any fraying, making it ideal for components requiring high aesthetic appeal. In handling foam, the machine's precision aids in producing complex shapes necessary for packaging and cushioning applications. When it comes to leather, the flatbed cutter offers consistency and detail, crucial for the fashion and upholstery industries. Reflective materials, often used in safety gear and signage, benefit from the machine’s ability to handle intricate designs with reflective precision.

Addressing Manufacturing Challenges

Manufacturers often encounter challenges in balancing speed and quality. The flatbed cutting machine addresses these concerns by offering high-speed operations without compromising on precision. It is equipped with customizable settings that allow users to tailor the cutting process to specific material requirements, thereby ensuring consistency and quality across large-scale production runs.

The Future of Cutting Technology

As industries push the boundaries of what is possible, the demand for innovative solutions like the flatbed cutting machine will continue to rise. Its role in enhancing cutting efficiency and versatility makes it a cornerstone of modern manufacturing. By investing in such technology, companies can position themselves at the forefront of industry advancements, ensuring they meet the ever-evolving demands of the market.

Ningbo Ruking Intelligent Technology Co., Ltd. Room 402, 4th Floor, Building 12, Xinchanyungu Industrial Park, Jiangkou Street, Fenghua District, Ningbo City, Zhejiang Province

Tel: +86-18167226377

Email: [email protected]

Copyright © 2023 by Ningbo Ruking Intelligent Technology Co., Ltd. Rights Reserved.

China Digital Cutter manufacturers Custom Digital Cutter Suppliers