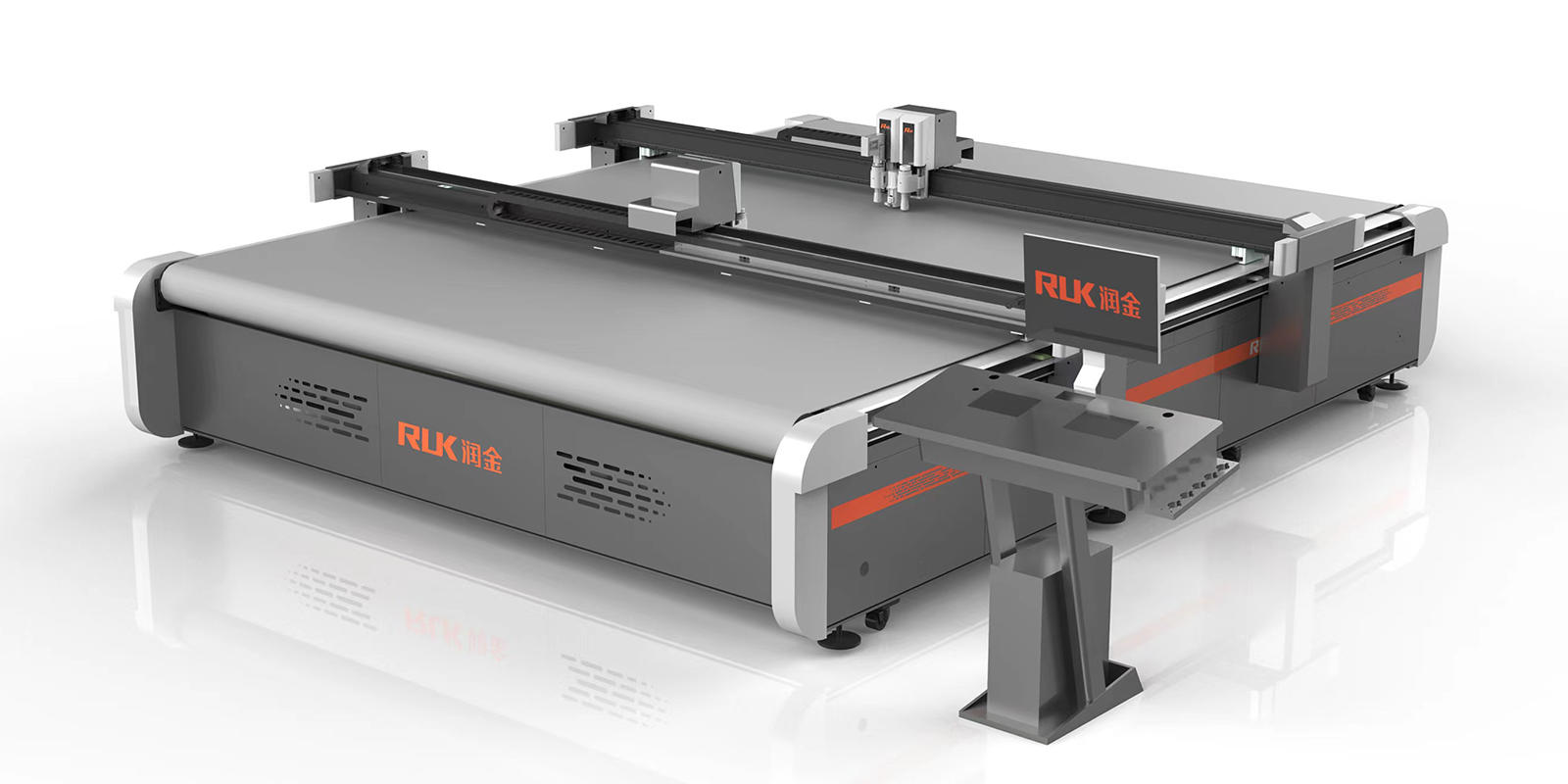

Professional Flexible Materials Automated Cutting Solutions.

1. Intelligent recognition system

Flatbed Cutting Machine is equipped with a high-precision intelligent recognition system that can quickly identify the edges of different materials. This system uses a high-resolution CCD positioning camera to automatically scan the material before cutting to ensure the accuracy of the cutting path. Traditional manual cutting is often affected by human factors, resulting in cutting errors, while the intelligent recognition system can eliminate these uncertainties and greatly improve the accuracy of cutting.

2. One-click QR code recognition function

The machine supports one-click QR code recognition, which can quickly achieve mixed cutting of multiple papers. This function greatly simplifies the operation process, allowing the cutting personnel to only scan the QR code, and the equipment can automatically adjust the cutting parameters to adapt to the characteristics of different materials. This intelligent operation not only improves production efficiency, but also reduces the cutting failure rate caused by improper operation.

3. Automatic tool setting function

The automatic tool setting function of Flatbed Cutting Machine makes the depth control during the cutting process more accurate. Traditional equipment usually requires manual adjustment of the tool depth, which is prone to human errors, while the automatic tool setting can automatically adjust the tool drop point according to the thickness of the material and the cutting method to ensure consistency and high quality of each cutting. This intelligent design significantly improves the reliability and efficiency of cutting.

4. Intelligent layered adsorption system

The intelligent layered adsorption system of Flatbed Cutting Machine achieves effective fixation of different materials by automatically turning on the adsorption function of the working area. When cutting multiple sheets of mixed paper, the system can flexibly adjust the adsorption strength to ensure that the material does not move during the cutting process, reducing the error in the cutting process. In addition, the system can intelligently identify non-working areas, turn off its adsorption function, reduce energy consumption, and optimize the use of resources.

5. User-friendly operation interface

The intelligent operation design of Flatbed Cutting Machine is also reflected in its user-friendly operation interface. The operation interface is simple and intuitive, and users can quickly get started without complex training. The interface provides real-time display and adjustment functions of cutting parameters, and users can flexibly set them according to production needs, which improves the convenience of operation.

6. Realize unattended operation

With the intelligent operation design, Flatbed Cutting Machine can achieve unattended operation. This feature allows the equipment to work uninterruptedly for a long time, suitable for large-scale production needs. In the case of unattended operation, the machine can still maintain efficient and stable operation, greatly improving production efficiency and reducing labor costs.

7. Adaptable cutting methods

The intelligent operation design of Flatbed Cutting Machine not only improves the flexibility of the equipment, but also adapts to a variety of cutting methods, including full cutting, half cutting, milling, etc. When facing different materials and complex cutting requirements, users can easily switch cutting modes through simple operations to ensure the quality and effect of the final product.

Ningbo Ruking Intelligent Technology Co., Ltd. Room 402, 4th Floor, Building 12, Xinchanyungu Industrial Park, Jiangkou Street, Fenghua District, Ningbo City, Zhejiang Province

Tel: +86-18167226377

Email: [email protected]

Copyright © 2023 by Ningbo Ruking Intelligent Technology Co., Ltd. Rights Reserved.

China Digital Cutter manufacturers Custom Digital Cutter Suppliers