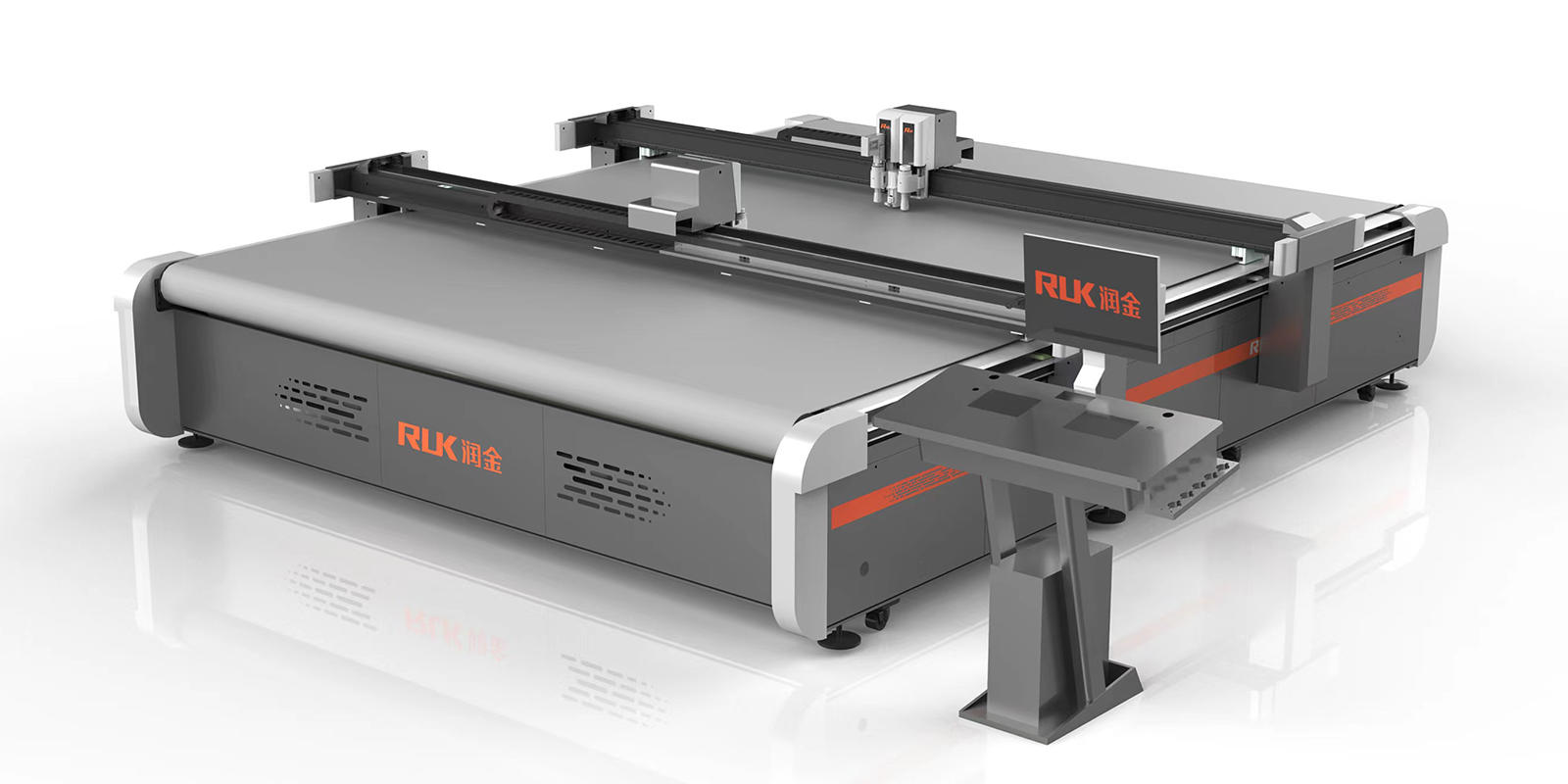

Professional Flexible Materials Automated Cutting Solutions.

1. Working principle of the intelligent layered adsorption system

The intelligent layered adsorption system of Flatbed Cutting Machine adopts an innovative automatic adsorption function, which can adjust the suction force according to the characteristics and thickness of different materials. The system ensures that the material is firmly fixed during the cutting process by precisely controlling the adsorption strength of each working area to prevent the material from sliding or deforming. Especially when processing multi-layer materials, the intelligent layered adsorption system can independently adsorb each layer to avoid misalignment caused by mutual slippage between material layers.

The built-in sensing device of the system can monitor the status of the material in real time, and automatically adjust the adsorption function when it detects changes or instability in the material. This flexible adjustment mechanism can achieve precise feeding, ensure accurate alignment of each layer of material, reduce errors caused by uneven or loose materials, and achieve the effect of zero-error feeding.

2. Reduce material misalignment and deformation

In traditional cutting equipment, material misalignment or deformation is the main cause of cutting errors. Especially when processing soft materials or multi-layer thin materials, a slight deviation in the feeding process may lead to inaccuracy in the entire cutting process. The Flatbed Cutting Machine can achieve precise positioning of the material when it enters the work area through the intelligent layered adsorption function, avoiding the misalignment or deformation of the material.

The intelligent adsorption system can adjust the distribution of suction according to the thickness and surface smoothness of the material to ensure the stability of each layer of material. For materials of different properties, the system will automatically adjust the strength of the suction so that each layer of material can be evenly attached to the work surface, avoiding the common problem of material slippage caused by uneven suction. Therefore, intelligent layered adsorption not only ensures the accuracy of feeding, but also improves the stability of the cutting effect.

3. Automatic identification and precise alignment

The intelligent layered adsorption function of the Flatbed Cutting Machine is combined with the automatic identification system of the equipment to further enhance the accuracy of feeding. Through the built-in high-precision CCD camera, the equipment can automatically identify the edge and shape of the material and locate the material in real time. This technology ensures that each layer of the material can be accurately aligned in complex shapes and mass production, avoiding the deviation that may be caused by manual operation.

In addition, the intelligent system can automatically adjust the suction force and the distribution of the adsorption area by identifying the size, thickness and shape differences of the materials to ensure that each layer of material is in the condition when it is fed into the working area. Through precise positioning and alignment, the Flatbed Cutting Mssachine can effectively reduce the cutting errors caused by material deformation or misalignment, thereby achieving zero-error feeding.

4. Energy-saving and efficient adsorption design

The intelligent layered adsorption function of the Flatbed Cutting Machine not only achieves zero-error feeding, but also focuses on efficient use of energy. The system adopts an integrated partitioned adsorption design, which automatically turns on or off the adsorption function in the working area according to actual needs, avoiding unnecessary energy consumption. For example, when the system detects that there is no material in the non-working area, it automatically turns off the adsorption function of the area, saving energy and improving adsorption efficiency.

5. Improve production efficiency and cutting quality

The implementation of the intelligent layered adsorption function has greatly improved the overall production efficiency of the Flatbed Cutting Machine. This function can automatically complete the feeding of multiple layers of materials without manual intervention, saving manual adjustment time and reducing the possibility of human error. Especially in mass production, intelligent layered adsorption can ensure efficient and precise cutting, greatly improving the efficiency and cutting quality of the production line. At the same time, with the realization of zero-error feeding, the scrap rate caused by material misalignment or deviation in production is greatly reduced, further optimizing production costs and improving the competitiveness of enterprises.

Ningbo Ruking Intelligent Technology Co., Ltd. Room 402, 4th Floor, Building 12, Xinchanyungu Industrial Park, Jiangkou Street, Fenghua District, Ningbo City, Zhejiang Province

Tel: +86-18167226377

Email: [email protected]

Copyright © 2023 by Ningbo Ruking Intelligent Technology Co., Ltd. Rights Reserved.

China Digital Cutter manufacturers Custom Digital Cutter Suppliers