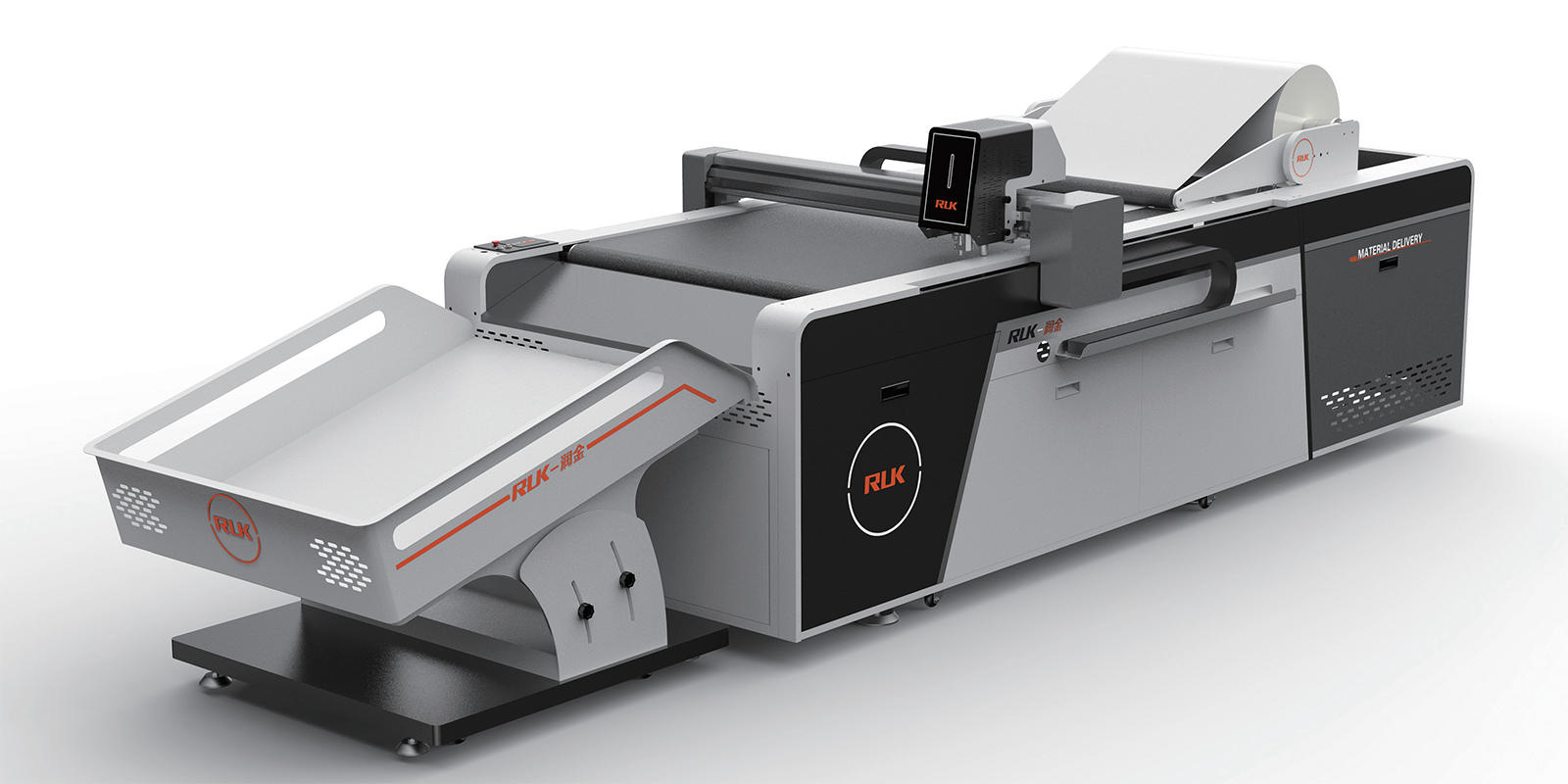

Professional Flexible Materials Automated Cutting Solutions.

In modern manufacturing, accurate cutting technology is the key to ensuring product quality and production efficiency. As a high-performance label cutting device, Sticker Label Cutting Machine is equipped with a CCD visual positioning system imported from Germany, which provides strong support for improving cutting accuracy and reducing cutting errors. This article will explore how to use this system to optimize the cutting process.

1. Working principle of CCD visual positioning system

The CCD (Charge-Coupled Device) visual positioning system monitors the edge of the cutting material in real time through a high-precision camera. The system uses high-definition image capture technology to accurately identify the outline and position of the material. The specific process is as follows:

Image capture: Before the machine cuts, the CCD camera will quickly shoot the material to be cut and generate a real-time image.

Edge recognition: Through the built-in image processing algorithm, the system can identify the edge of the material and compare it with the preset cutting path.

Error correction: When the system detects that the actual position deviates from the preset path, it can adjust the position of the cutting tool in real time to ensure the accuracy of the cutting.

2. Specific methods to reduce cutting errors

Real-time monitoring and automatic adjustment

Through the CCD visual positioning system, the Sticker Label Cutting Machine can monitor the position changes of the material in real time during the cutting process. Even if the material moves slightly during the cutting process, the system can respond quickly and automatically adjust the position of the tool to reduce the cutting error caused by material offset.

Adaptability of multi-layer material cutting

For the cutting of multi-layer materials, the CCD system can identify the edges of each layer layer by layer to ensure high accuracy during complex cutting processes. This multi-layer cutting capability enables the Sticker Label Cutting Machine to meet the needs of a variety of label products and further improve production efficiency.

Optimize cutting path

The CCD visual positioning system can not only identify the edge of the material, but also optimize the cutting path according to the actual situation. By analyzing the characteristics and position of the material, the system can adjust the cutting strategy to achieve more efficient cutting, reduce unnecessary cutting actions, and reduce material waste.

High-precision feedback mechanism

The CCD system of the Sticker Label Cutting Machine has a high-precision feedback mechanism that can record every step of the cutting process in real time. This mechanism enables operators to monitor cutting accuracy at any time and make timely adjustments when abnormalities are found, thereby effectively preventing error accumulation.

Ningbo Ruking Intelligent Technology Co., Ltd. Room 402, 4th Floor, Building 12, Xinchanyungu Industrial Park, Jiangkou Street, Fenghua District, Ningbo City, Zhejiang Province

Tel: +86-18167226377

Email: [email protected]

Copyright © 2023 by Ningbo Ruking Intelligent Technology Co., Ltd. Rights Reserved.

China Digital Cutter manufacturers Custom Digital Cutter Suppliers