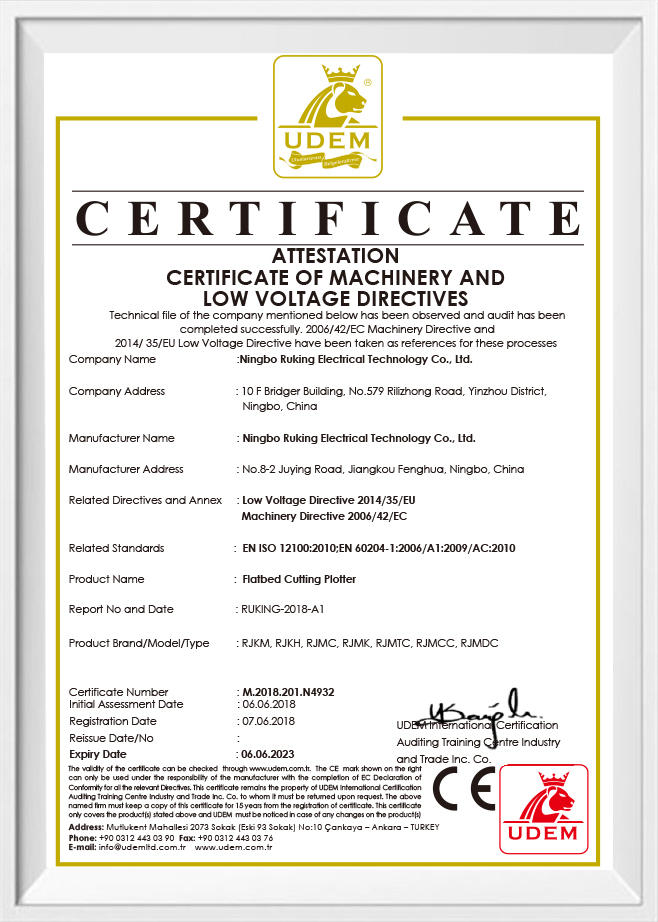

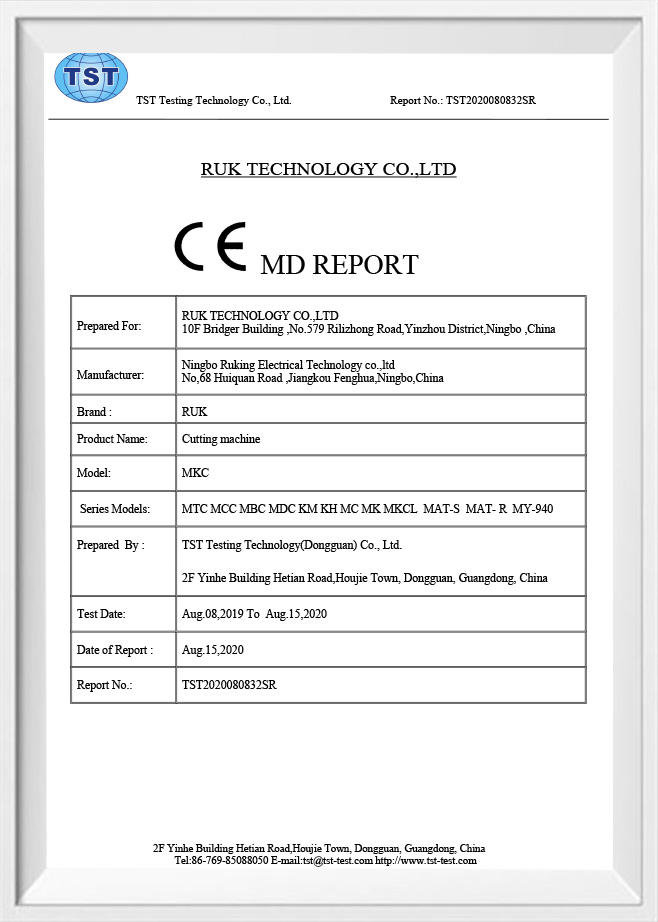

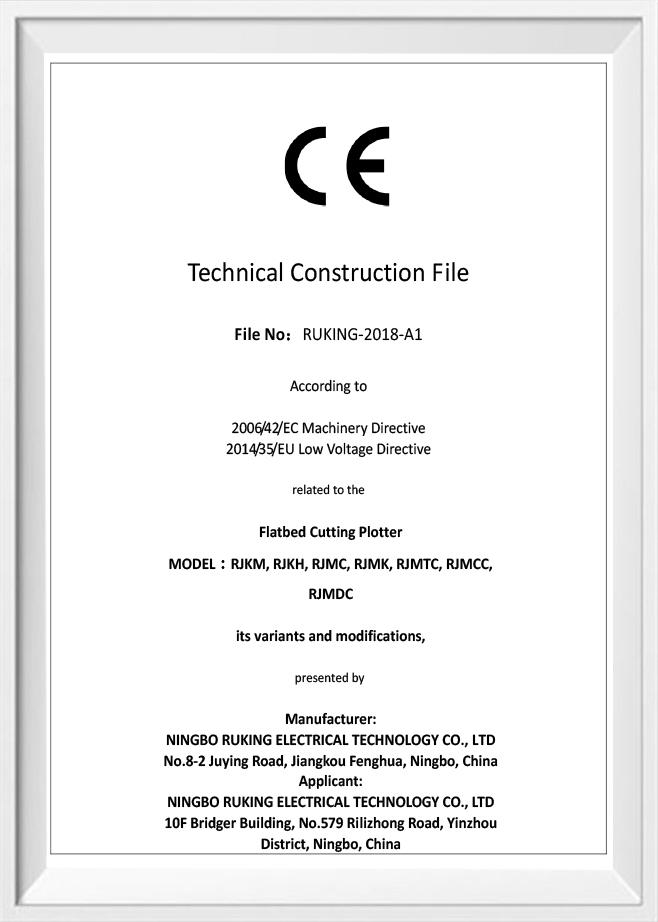

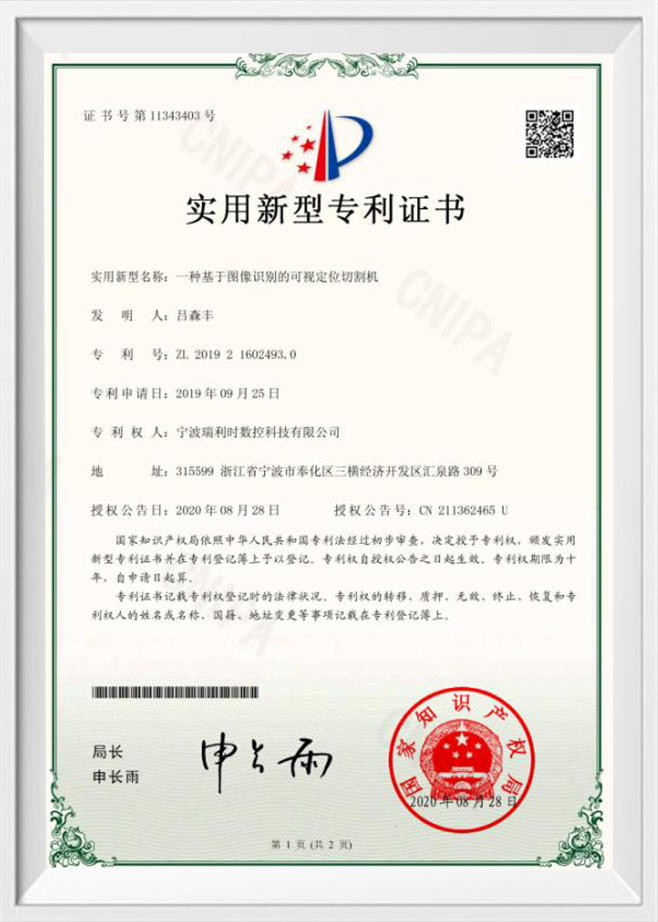

Ningbo RUKING Electrical Technology Co., Ltd is Automatic Sticker Label Cutting Machine Manufacturers and Automatic Sticker Label Cutting Machine Suppliers,a high-tech enterprise engaging in Industrial automation system, equipment and related spare parts, as well as its full set of program’s R&D, manufacturing, sales and service.RUK Tech owns a professional team consisted of competent and integrity people, who hold an important post on respective dept, machinery, electronics, computer software and management. We also have cooperation in program’s R&D with well-know university domestic and overseas, especially bringing in Europe’s technology and experts. We independently researched and developed CAD/CAM integrated NC cutting system, as well as controller and driving demanded in automation field.

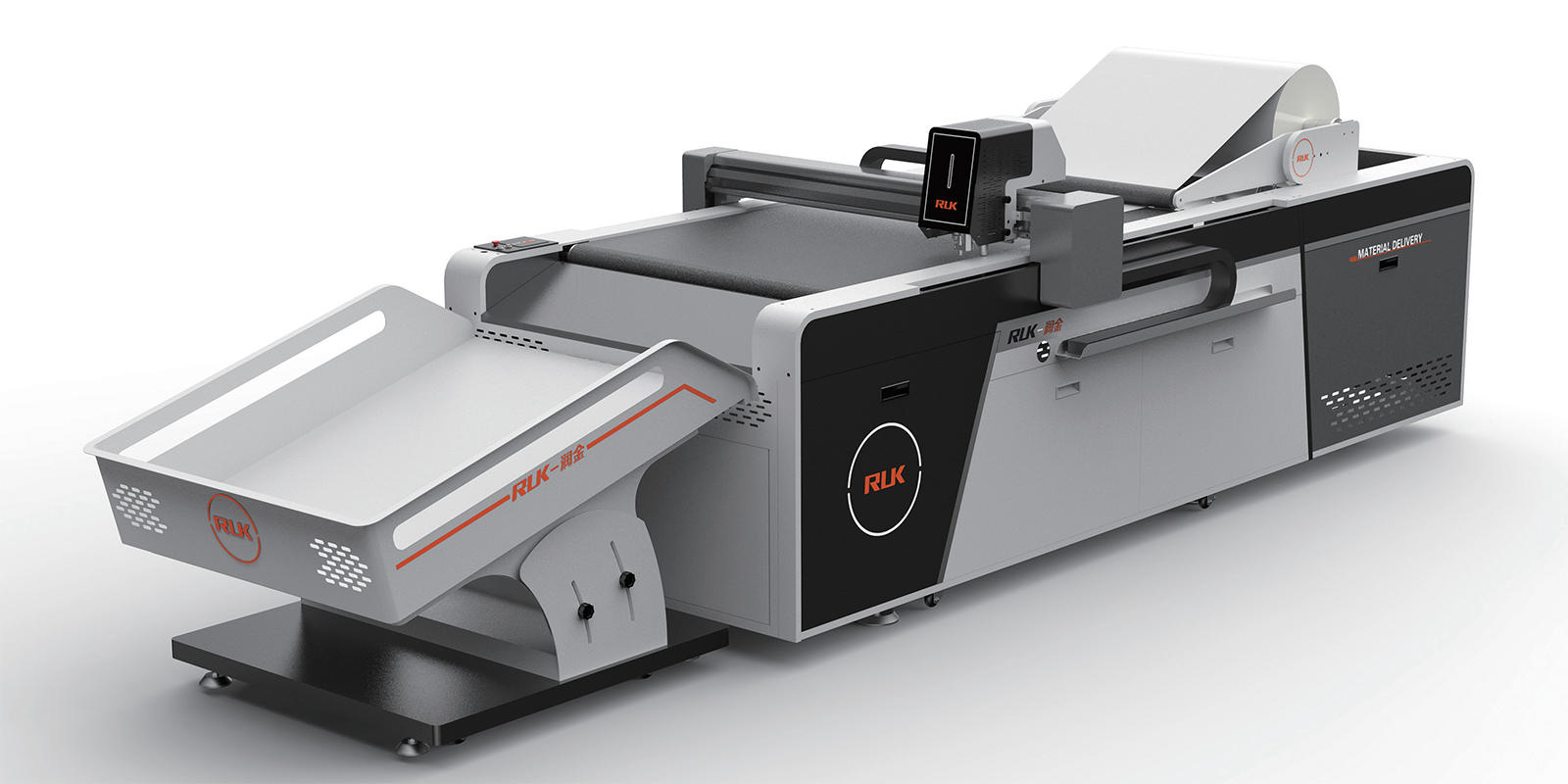

Intelligent Digital Cutting System Designed

for graphic advertising package and printing especially for some short run production

English

English Français

Français русский

русский Español

Español