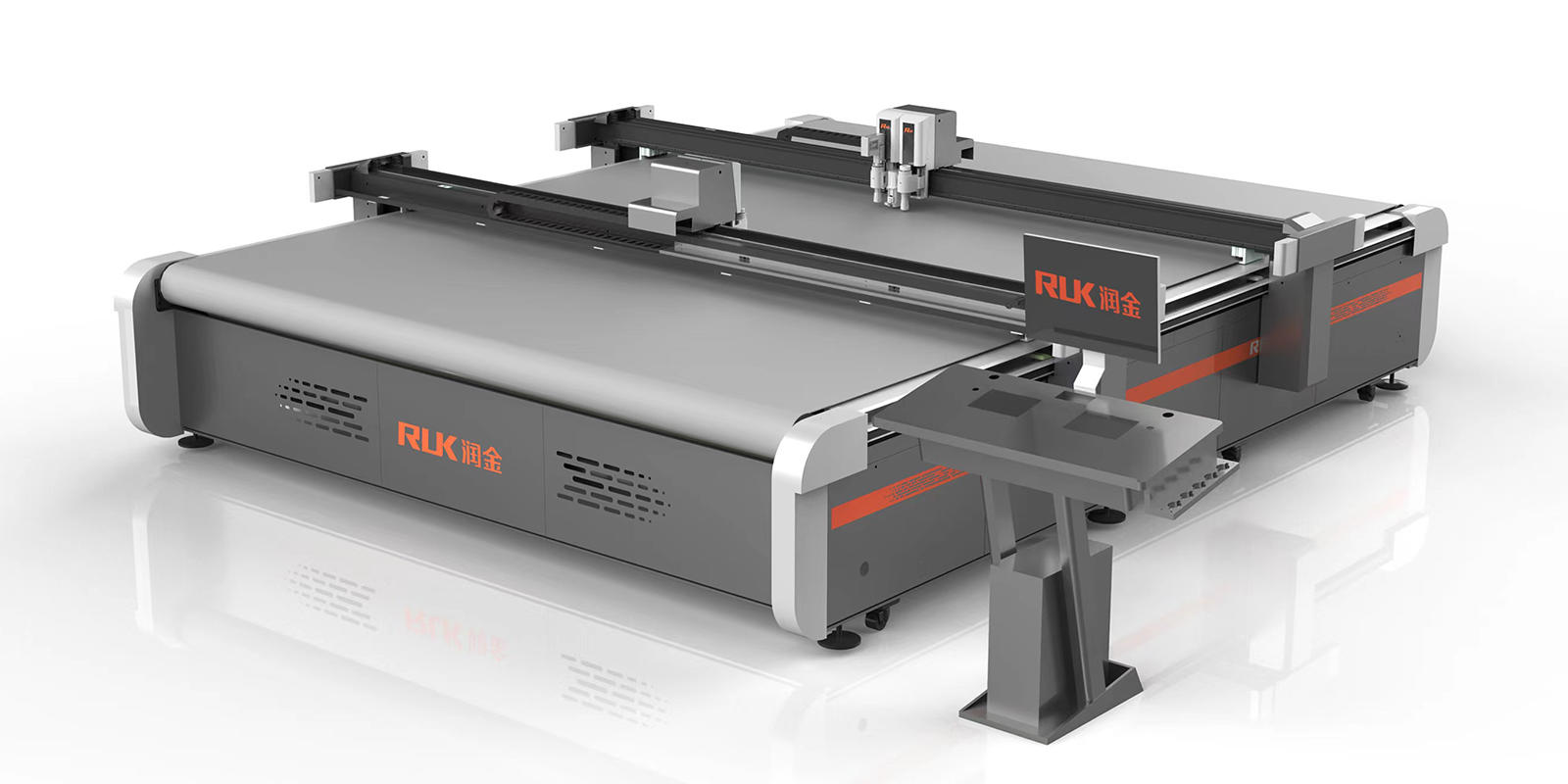

Professional Flexible Materials Automated Cutting Solutions.

Back-cutting technology is an important innovation in modern flatbed cutting machines. It significantly improves the efficiency and accuracy of cutting by changing the way the tool feeds. As a multifunctional cutting device, flatbed cutting machines are widely used in packaging, textile, printing and other industries. Their cutting accuracy and production efficiency are crucial to product quality and production costs.

Principles and advantages of back-cutting technology

In the traditional cutting process, the tool often enters from the front of the material. This method is prone to produce large tension and deformation, especially in the cutting of fragile materials such as film and paper. In contrast, the back-cutting technology uses the method of the tool entering from the back of the material, which can significantly reduce the tension transmission during the cutting process and reduce the risk of material deformation. It is particularly suitable for scenes with high cutting accuracy requirements.

Another advantage of back-cutting technology is that it reduces the friction when the tool contacts the material. Since the tool starts cutting from the back, the wear rate of the tool is effectively reduced. This not only extends the service life of the tool, but also reduces the maintenance cost during the cutting process, which is particularly important for production lines that run for a long time and are used frequently.

Practical application of flatbed cutting machine

Flatbed cutting machine is widely used in various industries, and the practical application of its back-cutting technology has enhanced its efficiency and reliability in the production process. For example, film cutting in the packaging industry, such as shaping cutting of plastic packaging bags, requires neat cutting edges without burrs to ensure packaging quality and beauty. Through back-cutting technology, flatbed cutting machine can accurately control the cutting depth and angle of the cutter to ensure clear cutting lines, reduce material waste and the need for secondary processing, and greatly improve production efficiency.

In the textile industry, flatbed cutting machine is often used for cutting and shaping of fabrics. Back-cutting technology helps reduce the deformation of materials during the cutting process and ensures the accuracy and consistency of the cut pieces. In the printing industry, the application of flatbed cutting machine is mainly concentrated in the post-processing and shaping of printed products, such as trimming of printed products and cutting of finished products. Back-cutting technology can ensure that the edges of each printed product are clear, improving the overall quality of the printed product.

Ningbo Ruking Intelligent Technology Co., Ltd. Room 402, 4th Floor, Building 12, Xinchanyungu Industrial Park, Jiangkou Street, Fenghua District, Ningbo City, Zhejiang Province

Tel: +86-18167226377

Email: [email protected]

Copyright © 2023 by Ningbo Ruking Intelligent Technology Co., Ltd. Rights Reserved.

China Digital Cutter manufacturers Custom Digital Cutter Suppliers