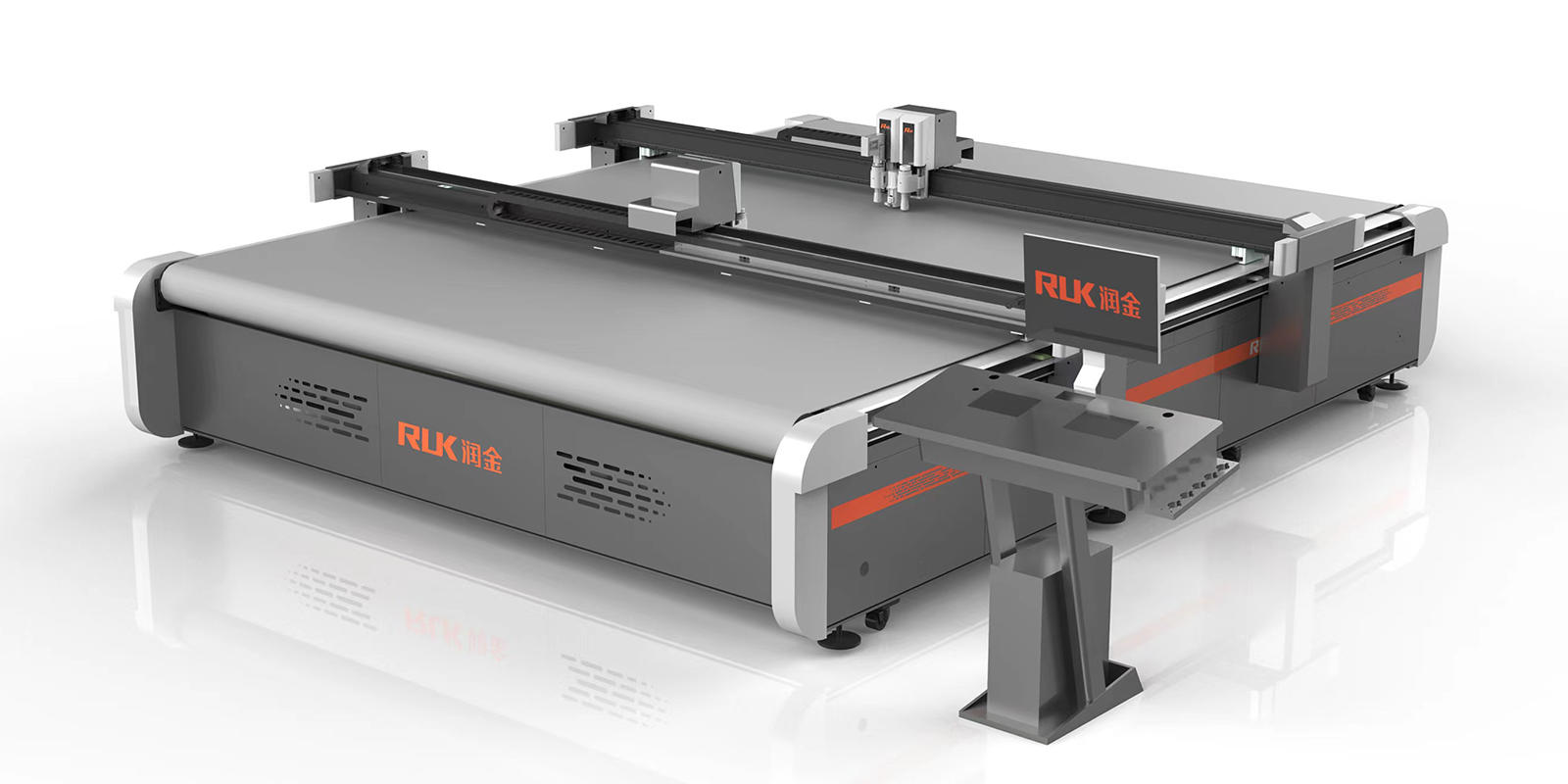

Professional Flexible Materials Automated Cutting Solutions.

Basic Principles of CNC Cutting Technology

CNC Cutting Technology (CNC Cutting) is a technology that controls the cutting path and cutting tools through a computer numerical control system. The operator first enters or imports the pattern and size to be cut on the computer, and the system then controls the movement, speed and depth of the tool according to the set parameters to achieve precise cutting. For Flatbed Cutting Machine, CNC cutting technology can not only improve accuracy, but also reduce human errors and improve production efficiency through automated processing.

Advantages of CNC Cutting Technology in Foam Cutting

The special characteristics of foam materials are that they have a wide range of densities, various thicknesses, and are extremely susceptible to cutting tools. Foams of different densities exhibit different physical properties during the cutting process, so how to effectively deal with these differences has become a challenge for Flatbed Cutting Machine. CNC cutting technology is the key to meeting this challenge.

1. Accurate path control

One of the biggest advantages of CNC cutting technology is its precise control of the cutting path. Regardless of the density of the foam, the Flatbed Cutting Machine controls the movement of the tool on a predetermined track through a preset path to ensure cutting accuracy.

2. Automatic adjustment of cutting depth and speed

The density of the foam directly affects the difficulty and accuracy of cutting. Softer foam materials generally require lighter tool pressure and higher cutting speeds, while high-density foams require deeper tool penetration and slower cutting speeds. Through real-time adjustment of the CNC system, the Flatbed Cutting Machine can automatically adjust the cutting depth and speed of the tool according to the different densities of foam materials to ensure consistency throughout the cutting process.

3. Intelligent path optimization

The CNC system equipped with the Flatbed Cutting Machine usually has an intelligent path optimization function, which maximizes the use of the foam material surface by optimizing the cutting sequence and tool movement path. This function is especially important for the cutting of large-format foam materials, which can effectively reduce the generation of waste and reduce material costs. In large-scale production, intelligent path optimization can also improve overall production efficiency and reduce unnecessary downtime.

Automatic selection and control of cutting tools

CNC cutting technology can not only optimize cutting paths and adjust parameters, but also automatically select the appropriate cutting tool according to different materials. Flatbed Cutting Machine is usually equipped with a variety of cutting tools, such as oscillating knives, rotary knives and cutting wheels, which are suitable for different types and densities of foam materials. Under the control of the CNC system, the Flatbed Cutting Machine can automatically switch the cutting tools to ensure the optimal selection and use of cutting tools when processing foams of different densities.

For example, when cutting low-density foam, the machine will choose to use an oscillating knife, which can achieve clear and neat cutting effects at higher speeds. When processing high-density foam, the deep cutting ability of the rotary knife can ensure the complete cutting of the material. Through CNC technology, the Flatbed Cutting Machine can flexibly switch between foam materials of different densities to meet various complex processing needs.

Ningbo Ruking Intelligent Technology Co., Ltd. Room 402, 4th Floor, Building 12, Xinchanyungu Industrial Park, Jiangkou Street, Fenghua District, Ningbo City, Zhejiang Province

Tel: +86-18167226377

Email: [email protected]

Copyright © 2023 by Ningbo Ruking Intelligent Technology Co., Ltd. Rights Reserved.

China Digital Cutter manufacturers Custom Digital Cutter Suppliers