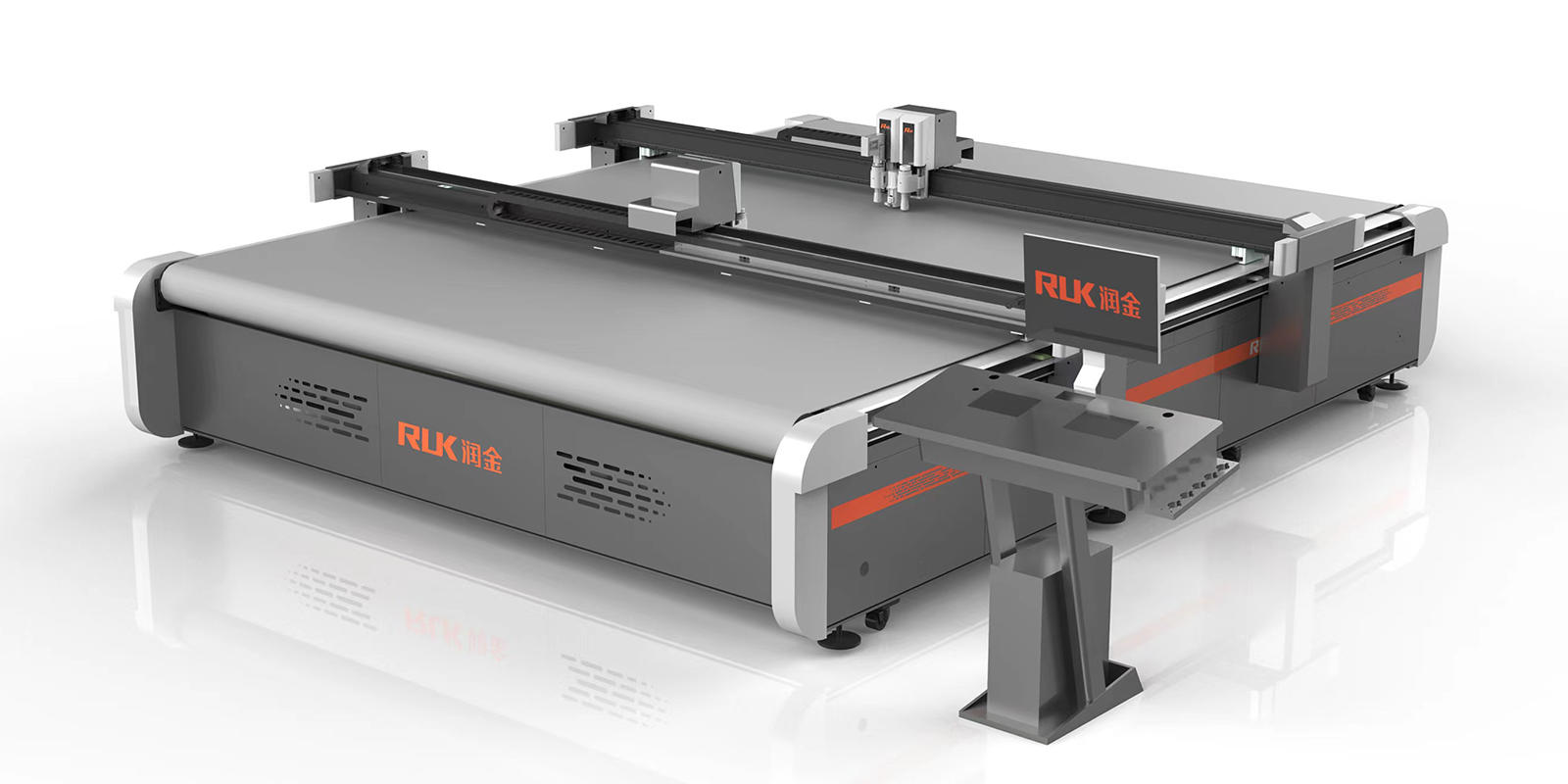

Professional Flexible Materials Automated Cutting Solutions.

1. Diverse material handling capabilities

Flatbed Cutting Machine is able to handle multiple types of materials, including paper, foam, plastic, leather, etc. Its powerful cutting capacity makes it suitable for mixed cutting of multiple papers, especially in the packaging, advertising and display industries. Whether it is thick paper, thin paper or special materials, Flatbed Cutting Machine can cut efficiently to meet the needs of different customers.

2. Combination of high precision and high efficiency

Flatbed Cutting Machine adopts advanced control system and high-precision gear rack structure to ensure high precision and high efficiency in the cutting process. The high-resolution CCD positioning camera equipped with the equipment can automatically identify the edge of the material, avoiding the error caused by manual operation. This feature is particularly important when performing mixed cutting of multiple papers, because different papers may have different characteristics, and accurate positioning and cutting can ensure that the cutting effect of each material is optimal.

3. Intelligent operation design

Flatbed Cutting Machine supports intelligent layer adsorption function, making the feeding process of different papers simpler and more efficient. The intelligent recognition system can recognize the QR code with one click, realize the mixed cutting of multiple papers, which is convenient to operate and reduces manual intervention.

4. Flexible cutting methods

Flatbed Cutting Machine has a variety of cutting methods, including full cutting, half cutting, milling and drawing, etc., which can cope with various complex cutting needs. This flexibility enables the equipment to flexibly adjust the cutting method according to the characteristics and cutting requirements of different materials when performing mixed cutting of multiple papers. For example, when processing thick paper, milling cutting can be used, while for thin paper, a fine half-cut method can be selected.

5. Efficient production capacity

Flatbed Cutting Machine has a high degree of automation and can work 24 hours a day, greatly improving production capacity. This feature is especially suitable for enterprises that need large-scale production. When performing mixed cutting of multiple papers, the equipment can quickly complete the cutting task to meet urgent production needs. In addition, the equipment has a low maintenance frequency and a low failure rate, which ensures the continuous operation of the production line.

6. Optimization of space and noise

The design of Flatbed Cutting Machine fully considers the utilization of space and the control of noise. Its built-in accessories are designed to meet the factory 5S and 6S management requirements, which not only saves space but also reduces noise. This optimization makes the operating environment more comfortable and improves the work efficiency of workers.

Ningbo Ruking Intelligent Technology Co., Ltd. Room 402, 4th Floor, Building 12, Xinchanyungu Industrial Park, Jiangkou Street, Fenghua District, Ningbo City, Zhejiang Province

Tel: +86-18167226377

Email: [email protected]

Copyright © 2023 by Ningbo Ruking Intelligent Technology Co., Ltd. Rights Reserved.

China Digital Cutter manufacturers Custom Digital Cutter Suppliers