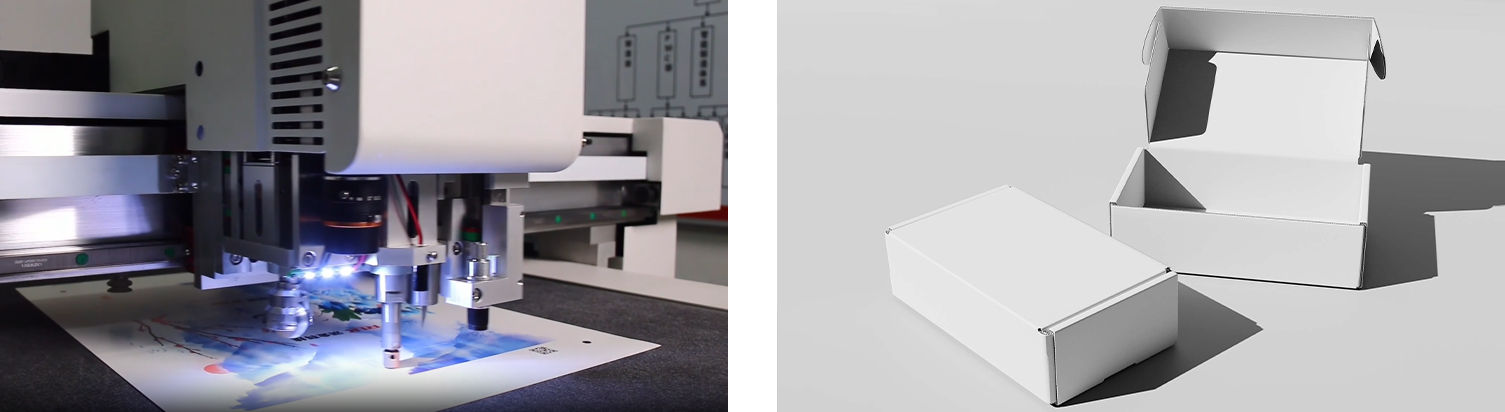

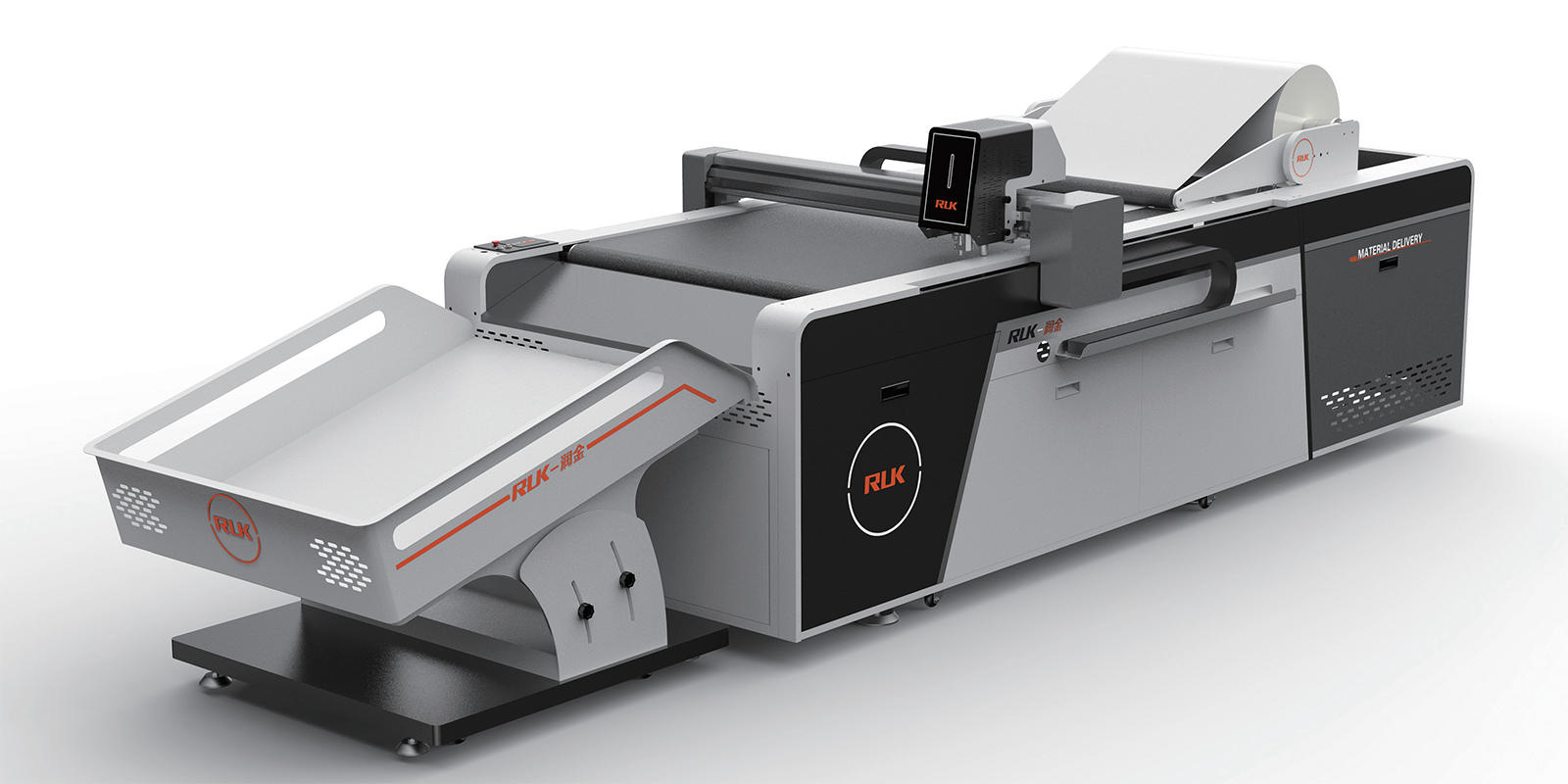

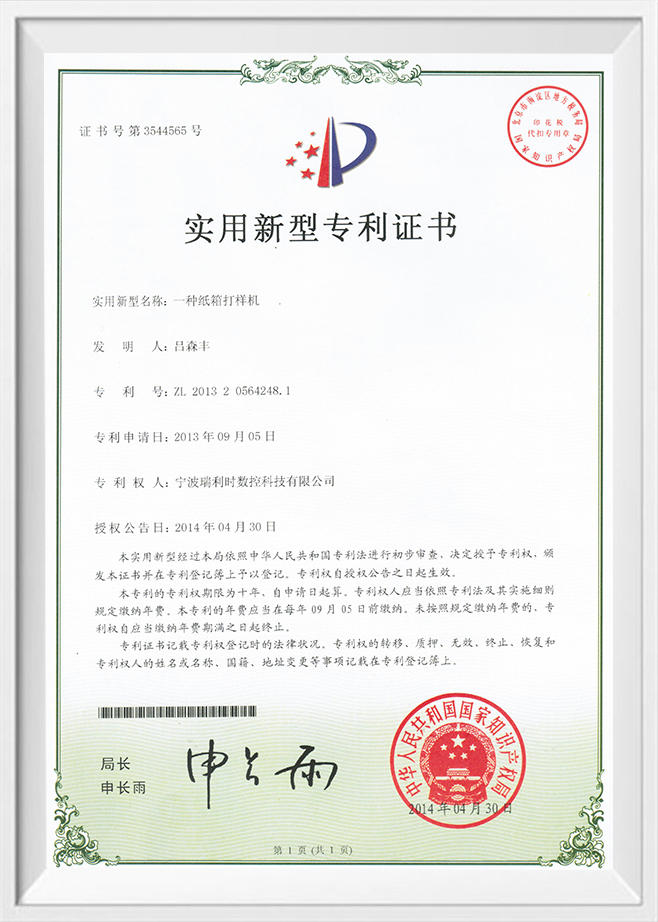

Printing and Packaging:

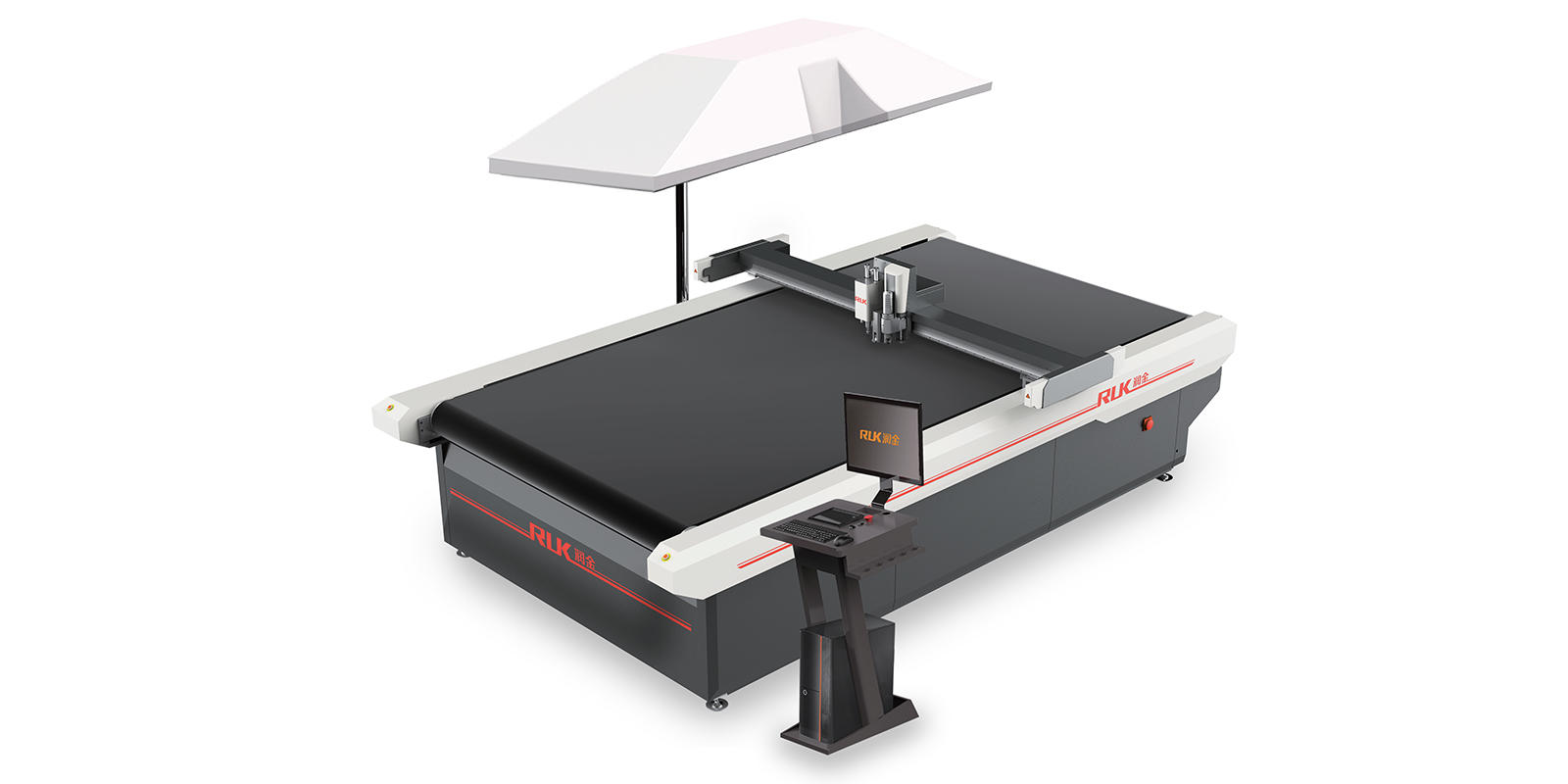

In the printing and packaging industry, fully automatic cutting machines have brought about a paradigm shift in the way materials like paper, cardboard, and plastic are processed. These machines are equipped with advanced software and tools for precise cutting, creasing, and scoring.

High Precision Cutting: Automatic cutting machines ensure the precise cutting of packaging materials, allowing for complex designs and shapes, which was difficult to achieve manually.

Speed and Efficiency: These machines can handle large volumes of materials quickly, reducing production times and costs.

Waste Reduction: The accuracy of automatic cutting minimizes material wastage, leading to cost savings and sustainability benefits.

Customization: They enable short-run and on-demand production of packaging materials, accommodating the growing demand for personalized packaging solutions.

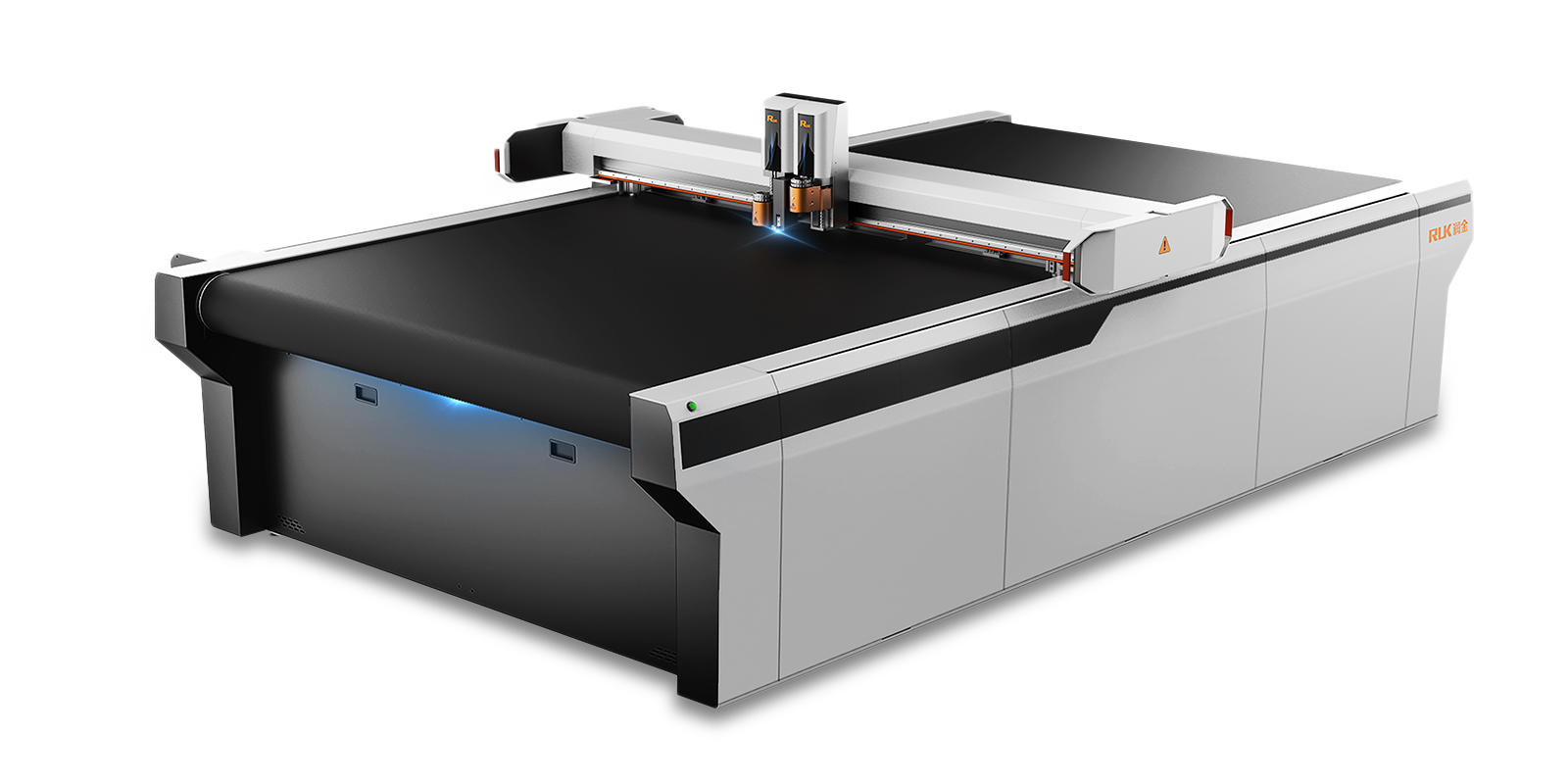

Advertising Graphics:

In the field of advertising graphics, fully automatic cutting machines have become indispensable tools for sign makers, graphic designers, and marketing professionals. They offer a range of benefits, including:

Precision Cutting: Automatic cutting machines can cut intricate shapes, letters, and logos with exceptional precision, enhancing the quality of graphics and signage.

Material Versatility: They can work with a variety of materials, including vinyl, foam board, acrylic, and more, enabling the creation of diverse advertising products.

Workflow Optimization: These machines streamline the production process, from design to final product, reducing labor-intensive manual work.

Cost-Effective Prototyping: Rapid prototyping capabilities allow for cost-effective testing of design concepts before full-scale production.

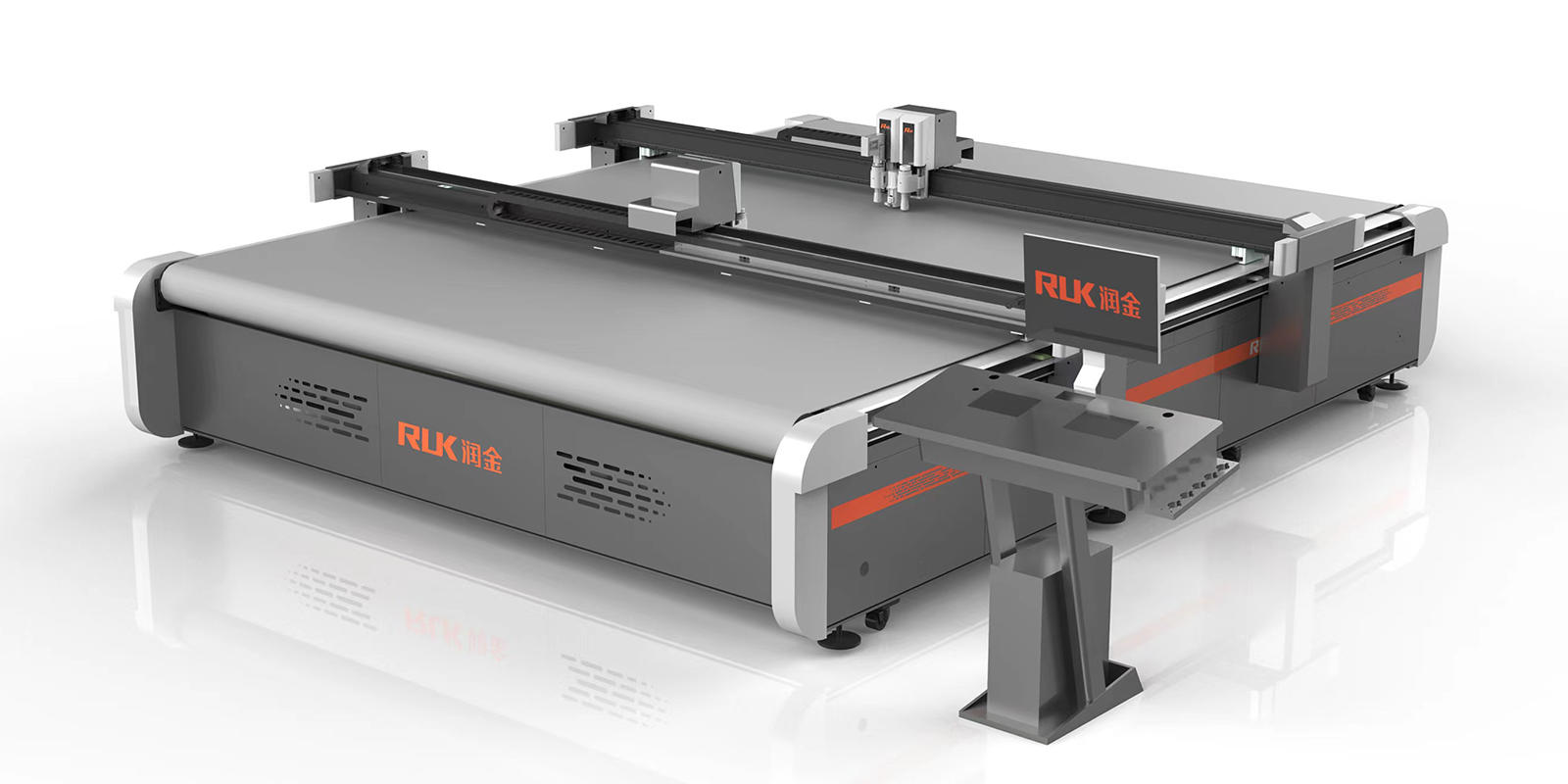

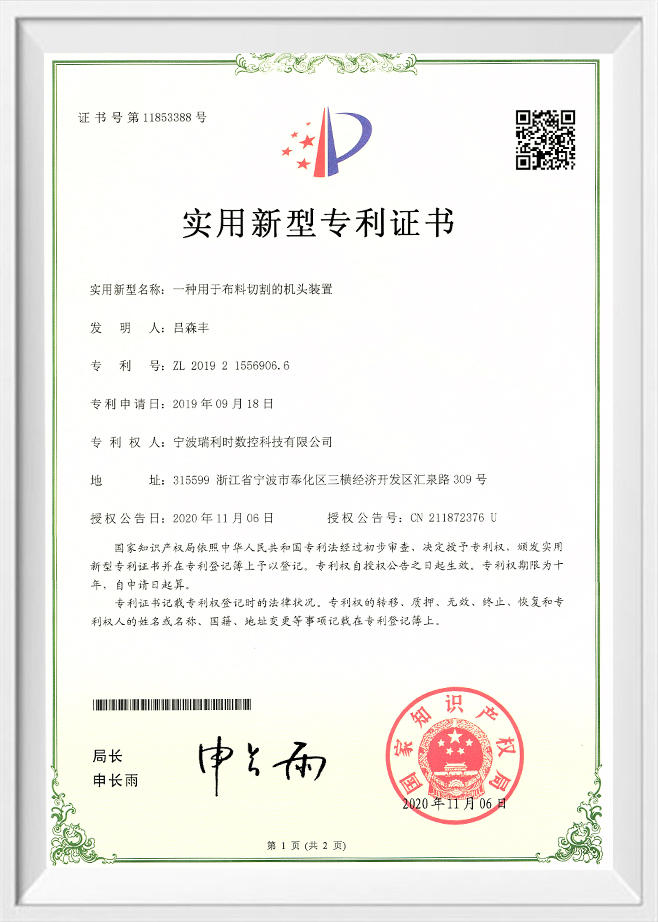

Clothing Fabric Cutting:

In the clothing and textile industry, fully automatic cutting machines have transformed the way fabric is prepared for garment manufacturing. They offer several advantages:

High Precision: Automatic cutting machines ensure accurate and consistent cutting of fabric, improving the quality of garments.

Reduced Labor Costs: These machines reduce the need for manual labor in the cutting process, leading to cost savings.

Efficiency: They can handle multiple fabric layers simultaneously, increasing production efficiency.

Pattern Management: Automatic cutting systems often come with pattern recognition software that optimizes the layout of pattern pieces on the fabric, minimizing waste.

Customization: In the fashion industry, they enable made-to-order and bespoke clothing production, catering to individual customer preferences.

In conclusion, the introduction of fully automatic cutting machines has had a transformative impact on the printing and packaging, advertising graphics, and clothing fabric cutting industries. These machines have revolutionized production processes by offering precision, efficiency, customization, and cost savings, thereby driving innovation and competitiveness in these sectors.

English

English Français

Français русский

русский Español

Español